A new garden shed is a major investment in your home and garden, as it should last for decades. Therefore, it is important to know how to choose the best shed for your garden and your garden storage requirements.

To help you select wisely, here are the most important things to consider before buying the best shed to meet your requirements.

Editor’s Note [26.09.23]: Our guide about how to choose the best shed for your garden was originally published on January 11, 2021. Today’s update includes the addition of extra details across many sections, also a new section about insulated shed characteristics has been added.

What is the Best Size Shed to Buy?

Firstly, assess how much space you have in your garden for a shed. This will help you narrow down your choices and identify which are the best garden sheds for your space – the best size shed for your needs.

Think about space for maintenance of the exterior, extra room for doors or windows to open, and any overhead obstacles such as branches or wires.

Our advice is to go large. As large as you can, you will need ample room for garden tools and other items as the years progress.

Trust us, it’s very easy to fill a shed, whatever its size, and there is nothing more frustrating than running out of garden storage space.

Be aware that garden shed sizes are often rounded for product naming purposes. Therefore, a 6’ x 4’ shed may actually be 6’2” x 4’5”. It is essential to ALWAYS check the detailed specification. This will also show if there are any roof overhangs that you need to consider.

A corner shed is worth considering if maximising outdoor living space in a smaller garden is a key issue. Cleverly designed corner sheds make the most of a neglected corner of your garden.

Nothing beats getting out some string and stakes to plan out where your corner shed will go.

Shed Usage

Before you start looking at the best garden sheds for you, bear in mind the requirements of different uses for a shed. It may be depending on usage, that you may want to consider other garden buildings as an alternative such as a summer house, a garden office, or a log cabin, etc.,

Storage for gardening supplies such as garden furniture, gardening tools, garden accessories and garden essentials, a spade or two, a bag of compost and a small mower is less demanding than the requirements for securing more valuable, bulky equipment such as chainsaws, ride on lawn mowers and cultivators. You’ll need to consider security, double doors, and floor strength if you plan to store these!

A workshop shed will need to be bigger to allow you to work comfortably. You’ll need to understand the natural light available to consider your need for windows or skylights, headroom, and space for staging such as worktables or shelves.

For a potting shed, extensive glazing is essential. Most potting sheds come with a whole side of glazing, as well as a single door and additional opening windows to help regulate the temperature of the plants and when you’re hard at work inside. As well as glazing, a potting shed needs to consider space for storage and a potting table.

For a security shed, perhaps to store your best garden tools or more valuable DIY equipment, you’ll want to consider high-level or no glazing at all, shed security features and overall strength of construction.

Taking the time to consider the purpose of your garden shed, will help narrow down the options and maximise your chances of buying the best garden shed for your needs and the best size shed for you.

Best Sheds by Material - Wood, Metal or Plastic Shed?

Many homeowners make this decision instinctively. But do you really know the different benefits and limitations of wooden, plastic and metal sheds and which will make the best garden sheds for your property?

Best Wooden Sheds

We all know where we stand with a traditional wooden shed.

They are relatively easy to assemble and are sturdy sheds that will complement your garden’s natural environment. Timber sheds are also the easiest to customise with shelving, hooks, and paint colour.

If you do opt for one of our best wooden sheds, you’ll need to consider the cladding which is the way the walls of the shed are constructed.

Overlap Cladding

This is the cheapest option. Overlap sheds are built by fixing the wooden boards to a timber framework in a horizontal, overlapping fashion.

The slats are generally 7-8mm thick, providing good all-round protection.

They can be prone to warping and gaps if the shed is not built properly on a level, solid standing. They can be draughtier than the other options too.

That being said, overlap sheds have stood the test of time as the most popular shed construction methods and have proven to be a reliable garden storage shed in countless gardens and allotments.

Shiplap Cladding

These sheds are constructed using tongue and groove interlocking boards for a weather-tight finish. Shiplap differs from standard tongue-and-grove as it has a scalloped front for a different aesthetic which is also considered ideal for encouraging rain runoff.

Shiplap sheds have a sturdier build than overlap, generally being built from 12mm wooden boards.

Tongue and Groove Cladding

Tongue and groove sheds are similar to shiplap and are usually regarded as being the highest quality wooden sheds.

They are built from interlocking timber boards, with a cladding thickness of at least 12mm.

This tight join creates a reliable seal against both draughts and moisture.

Without the scallop of shiplap, the standard tongue and groove has a flat finish which is considered more appealing in modern gardens. Most are also smooth planed which makes for a very smart appearance.

Best Metal Sheds

Although reputedly the most difficult to assemble, the best metal sheds tend to be the strongest and most secure.

Most modern metal sheds feature anti-rust finishes so are not susceptible to the gradual rot of wooden sheds or pest infestation. As such, they are very low maintenance too. Metal sheds often have very long guarantees to support their robust builds.

With many colours now available, choose from our best metal sheds collection, which is ideal for a modern garden.

Best Plastic Sheds

Deceptively lightweight during construction, the best plastic sheds often have metal frames which, once fully constructed, create a formidable storage shed.

Advances in plastic mean that many plastic sheds are stronger than ever before and are also UV protected. UV protection prevents the yellowing of the plastic over time and the cracking of the material under differing temperatures.

These advancements also offer plastic sheds better guarantees than you would expect if when you think of plastic in the garden you think of old-fashioned plastic chairs that break easily.

Plastic sheds are available in a huge range of designs, colours, and sizes. Some even mimic the appearance of timber for the best of both worlds.

Almost maintenance-free, easy to build and reliable, buying one of our best plastic sheds means you can enjoy top-quality garden storage without the premium price tag.

If you choose a plastic shed then be sure to check its specification if you intend to drill holes in the walls for shelving, as this may not always be possible.

Roof Design

Choosing your roof design will be influenced by where you will be positioning your shed as well as your aesthetic preference.

Apex Sheds

A classic shed option, the apex style is where the 2 roof panels fit together to create a triangular point along the centre of the roof. The single door or double doors will be under one of the gable ends.

This design offers more headroom along the centre of the garden shed and is useful for storing taller garden equipment.

Apex roofs are viewed as the traditional option and are the most popular choice of shed roof.

Pent Sheds

Pent roof sheds are ideal for gardens with lots of trees as they have a lower profile than other shed roofs. They are also suited to placement up against a fence or wall when you buy one of our lean to sheds.

The roof is slanted towards the back of the shed, usually leaving the door on the highest side.

Pent roofs are seen as the more modern option due to their sleek lines.

Reverse Apex Roofs

Like an apex shed, the roof reaches a peak along the middle of the shed. However, instead of under a gable, the single door or double door is positioned on one of the shed’s longer sides.

A reverse apex shed roof is a popular choice for a garden workshop as the door placement allows for optimised use of the space for workbenches and manoeuvring.

Flooring

Most wooden and plastic sheds come with floors as standard, but this isn’t usually the case with a metal shed, where you may need to purchase the flooring as an optional extra.

The type of floor you require should be determined by what you wish to store. The heavier the gardening tools and equipment, the thicker the floor required. Thicker floors are a common feature in a heavy-duty shed.

OSB (Oriented strand board) floors are most common in cheaper sheds. They are usually reliable but may sag or soften if exposed to too much moisture.

Timber boards or tongue and groove flooring will be stronger and offer greater protection against ground moisture.

As a general rule of thumb for wooden floors, 12mm tongue and groove and thicker is considered very high-quality shed flooring.

Also, look for pressure treated floor bearers. Even an OSB floor may be supported by these rot-resistant supports, helping to extend the life of the shed and the floor.

What are the characteristics of a best insulated shed?

A best insulated shed possesses several key characteristics that set it apart:

- Effective temperature control - this is paramount and is achieved through high-quality materials such as closed-cell foam or mineral wool insulation, ensuring minimal heat transfer

- Air sealed – there are impeccable air sealing seals gaps, which prevent drafts and maintain a consistent internal temperature

- Moisture control - optimal design includes appropriate ventilation to regulate moisture and prevent condensation

- Energy efficiency - a best insulated shed maximises energy efficiency, creating a comfortable environment for various uses

Level of Shed Maintenance Required

How much time you have available to maintain your shed will also factor into your shed buying decision.

Wooden Sheds

All wooden sheds require treatment with a high-quality wood preservative. This helps prevent rot and fungal decay, so prolonging the life of the shed.

When you purchase a wooden shed it will usually be treated in one of two ways:

1) Dip Treated Sheds

Here, as the name suggests, the timber is dipped in wood preservative. This provides a good level of surface protection, but the shed will need retreating, sometimes upon assembly, and always on an annual basis.

Dip treated sheds can often be recognised by the wood’s orangey hue.

2) Pressure Treated Sheds

During this treatment, preservative is forced, under pressure, into the wood. The preservative essentially becomes part of the timber, providing a more comprehensive level of protection.

Pressure treated sheds require no further treatment, saving you time and, in the long term, money that would be spent purchasing and applying tubs of treatment.

Metal and Plastic Sheds

High-quality metal and plastic sheds are not susceptible to rot. If located in a damp area, there may be a superficial build-up of algae and, of course, dirt. If so, both metal and plastic sheds can be maintained with the occasional wipe down using soapy water or a power washer.

Shed Security Required

Of the available materials for a shed, metal is considered the most secure as it is the hardest to penetrate. Some metal sheds feature sophisticated 3-point or 5-point locking systems for extra security and ultimate peace of mind.

Windowless sheds or sheds with a high-level row of smaller windows are more suited to security. They block the view of any valuable items inside (e.g., expensive tools) and do not offer another potential entry point.

Sturdy doors that feature double bracing will be stronger. Also, hidden hinges and tamper-proof screws will deter easy access.

Some sheds only have turn buttons and others have a hasp and staple which will require you to add your own padlock. More secure sheds will have a key-operated lock for the greatest deterrent.

Budget

This is probably the biggest question and, therefore, the starting point for many potential shed owners.

If you have under a hundred pounds, you'll be looking at garden storage units such as garden chests, outdoor storage boxes etc., Double that and you are in shed storage territory.

Generally, but not always, a plastic shed is the cheapest option. However, wider shed specification plays a significant part in determining price too. The bigger the shed generally means the more money you’ll have to spend. The more shed features - such as glazing, key-operated locking systems, double doors, etc., – the more you should expect to pay.

Regarding wooden sheds, the cladding thickness and type of timber treatment play a big part in price too.

When comparing garden shed prices, bear in mind what is included. Some workshops will include installation and other garden sheds will include a floor in the price; meanwhile, other sheds will offer these as a purchasable extra.

What About Shed Accessories?

From shelving to solar power there are many accessories available to optimise working in your shed.

For adding your own shelves and hooks, wood has the edge over the other options as all you need are some screws and a screwdriver.

That said, metal and higher-priced plastic sheds can be adapted too often with the manufacturer’s product-specific extras.

Take a look at the accessory options of a product to see if there are any suggested products that may make life easier.

How Are Your DIY Skills?

You may want to consider the ease of building different garden sheds depending on your do-it-yourself skills. The best sheds for you may be the easiest ones to build!

Plastic sheds are the lightest to handle and are quite easy to assemble. Some of the high-tech engineered plastic walls may appear flimsy during construction but once completed, can offer excellent strength and are virtually unbreakable.

Metal sheds have long been considered the most difficult to build due to the number of screws. However, manufacturers have been working hard to make an easier-to-build metal shed with fewer parts.

Wooden sheds are somewhere in between the two. Wood is easy to work with but does require accurate alignment during the build.

If you are not confident with DIY, many of our manufacturers offer an installation service via their own teams of experienced shed fitters. Fast, professional and no effort required from you – a great idea!

Other Important Shed Buying Tips

When Should I Buy My New Shed?

The simple answer is that there is never a bad time to buy a shed. When you need a shed is a different matter. Here are some potential reasons:

Your Shed is Shabby, Not Chic

Neglected wood is rotting or the ancient plastic cracking, it is not the charming shabby chic style; it's simply shabby.

An ailing shed won’t be providing effective protection for your stored items. That leak could ruin your garden furniture. Those draughty gaps could let in critters to nibble your valuables. You've intended to replace it for years, and now is your opportunity to do so.

You’ve Outgrown a Small Shed

Your small shed is packed with gardening tools and miscellaneous items, straining at its seams with audible creaks.

It takes ages to get things out and your shins take the brunt as you manoeuvre machines over bamboo canes, desperately trying not to dislodge other stored items.

Year after year, garden furniture finds itself submerged within the dim confines of the shed, just as thunderclouds gather, and the mower, dormant for a month, is extracted and manoeuvred out of the shadowy corners of the shed, coinciding with the resurgence of grass growth.

For your garden’s sake and that of your shins, it is time to get a bigger shed. Your stored items are less likely to get damaged as you wrestle them in and out. Plus, you’ll save time searching for buried items or restacking the tower of contents every time.

If you are dismantling an old shed, choose a dry day so the stored items are not damaged by rain or wind. You can list your old shed on different websites for those interested in disassembling and collecting it.

Alternatively, you could visit the allotment site and inquire if anyone is interested. Even a shed with leaks could be valuable to an enthusiastic allotment gardener.

However, be cautious: dismantling a shed older than five years can be challenging. It will require two individuals and a considerable amount of patience.

Your First Shed

You may have bought a new home or just gradually acquired enough garden equipment to require a proper garden shed.

Hopefully, this guide will have helped you choose the perfect shed for your garden.

Shed Installation

Though focused on choosing your shed, it can be helpful to think ahead to installation. Here are a few shed building matters to consider.

Shed Bases

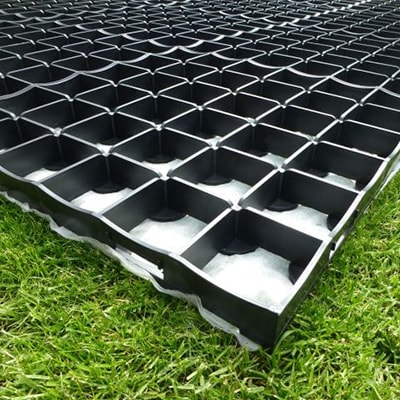

There are four main types of shed bases: poured concrete, paving slabs, wooden bases, or plastic grid bases. If you have an existing shed base, you will need to check that it is still solid, level, and suitable for your new shed. Having the right shed base is critical.

If you require a shed base, there are two methods to consider. Both require levelling and firming out of the grassed or earth area.

The first option is a hardstanding base, such as poured concrete or slabs. You can engage a tradesperson to do this.

The other option is a base which lies on top of the ground and a sheet of membrane. This can be a wooden base or a plastic grid base. This is an easier DIY option but still requires proper ground preparation.

DIY Installation

As mentioned previously, many of our manufacturers offer an installation service via their own teams of experienced shed fitters. Be aware that ground preparation and base installation are not included in any manufacturer’s shed installation service.

If you decide to install the shed yourself, choose a dry day and you can reasonably expect to go from an empty plot to a fully operational and replenished garden shed within a day.

Make sure you have helping hands-on site. Building a shed is a two-person job at minimum.

Concluding Thoughts

In the quest for the best shed, several key considerations come into play. Determining the ideal shed size depends on available garden space, with larger options often being preferable for accommodating future storage needs. Wooden sheds offer a timeless aesthetic and can be tailored to individual preferences.

When looking for the best insulated shed, focus on effective temperature control, proper air sealing, moisture regulation, and energy efficiency. Factors like shed usage, security requirements, budget, and DIY skills also contribute to making an informed decision.

Ultimately, choosing the best wooden sheds, the optimal size, and a well-insulated design enhances both functionality and aesthetic appeal for your outdoor space.

Need More Help Choosing Your Best Garden Shed?

You can find all our high-quality, great value garden sheds here.

Our UK-based, friendly customer service team will be happy to answer any questions you have about how to choose a best garden shed. You can contact Shedstore by phone at 0333 003 0518, by live chat on the website or by emailing us at [email protected].

We hope you enjoy your new shed for many years to come!