My Basket

Checkout using your account

Checkout as a new customer

Creating an account has many benefits:

- See order and shipping status

- Track order history

- Check out faster

- Home

- Buying a Shed Guide

Buying a Shed Guide

A shed is an essential part of any garden. It not only provides invaluable outdoor storage for garden equipment and furniture, but can make a great garden workshop for DIY and other projects.

As a garden shed is a big investment and should last for decades without needing to be replaced, it is essential to be aware of all the steps you need to take when choosing a shed.

As one of the UK’s leading suppliers of sheds and garden buildings, Shedstore are experts in how to choose the best shed. Our guide covers all you need to know.

This guide will cover the topics below. Click a topic to go straight to the information you need.

Step One: Choosing the Size

Step Two: Choosing the Material

Step Three: Understanding Shed Treatment

Step Four: Choosing the Cladding

Step Five: Roof and Floor Information

Step Six: Window and Doors Information

Shed Base Information

Shed Electrics

Great Shed Ranges to Consider

Shed Delivery

Shed Installation

Contacting Us

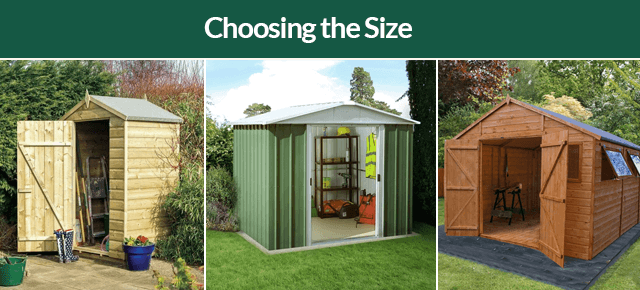

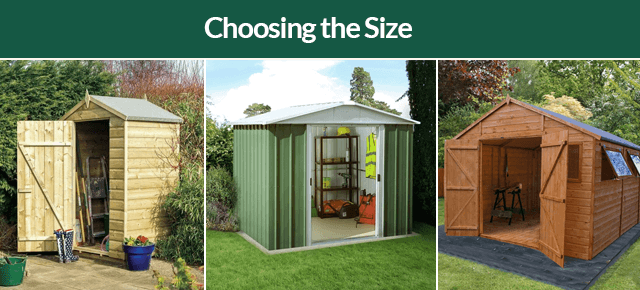

Step One: Choosing the Size

Find the best location for the shed. Pay attention to whether it affects views from the house and any seating areas in the garden.

Measure the location and mark it out. Remember to include 1-2 feet of space around the perimeter of the shed for treatment and maintenance, particularly if buying a wooden shed.

Consider what will be stored in the shed now, as well as future needs. A small shed makes the ideal home for a basic selection of garden tools. For a bike or ride-on mower, something bigger is required. A 10x6 shed is usually the minimum for a comfortable workshop.

Calculate your budget. Consider the cost of the shed, installation and base materials.

Having considered location, use and budget, the size of shed required should be clearer.

Remember to check the shed’s specification details and whether these include overhanging roofs, log stores or other features. Make sure there is space for doors and windows to open.

Now you are ready to consider which material is best for your shed.

Shop by Popular Shed Sizes

Wooden Sheds

A wooden shed’s traditional appearance helps it complement the natural aspects of a garden. Wood sheds are also the easiest to customise with shelves, hooks and insulation. Their only downside is that they need maintaining. A dip-treated wooden shed requires treating with wood preservative annually, although a pressure-treated model could be left untreated for up to 25 years without any danger of rot.

Metal Sheds

Metal sheds are known for their strength and durability. As such, they usually come with long guarantees. They are also renowned for their excellent security, so are a great choice for storing valuable tools and equipment. Available in a range of colours and designs, there’s a metal shed to suit most types of garden. Be aware that they are usually more difficult to assemble than wooden or plastic alternatives.

Plastic Sheds

Nowadays, there are some incredibly high-quality plastic sheds on the market. They are strong, long-lasting and very low maintenance sheds. Available in a range of colours and styles, some plastic sheds are designed to resemble other materials; many are supported by robust metal frames; and most are UV-protected to maintain their attractive appearance.

Dip Treatment

Dip-treatment is where the manufacturer applies a coat of preservative to the wood’s surface to protect it against rot and fungal decay. Although this ensures a decent level of protection, the shed will require retreating annually, and sometimes upon assembly too. Dip-treated sheds can usually be recognised by their orangey hue. They tend to be cheaper than pressure-treated sheds but are usually still supplied with excellent guarantees of up to 10 years, when supported by annual retreatment.

Pressure Treatment

Pressure treatment involves the preservative being forced deep into the wood, ensuring an unbeatable level of protection against rot and fungal decay. In most cases, this means that the shed will not require retreating for up to 25 years, saving time and money. Pressure-treated sheds are paler in colour than dip-treated ones. They tend to be a little more expensive but the 25-year guarantee and less maintenance are worth the small extra cost.

Cladding refers to how the walls of the shed are constructed. There are three types of wooden cladding: overlap, shiplap tongue & groove, and standard tongue & groove.

Overlap Cladding

Overlap cladding is the simplest way to construct a shed, so is also the cheapest. The boards are nailed to the shed’s frame in an overlapping fashion, allowing the timber to naturally contract and expand over the course of the year. Overlap sheds are usually constructed from thinner boards, so are more prone to damp and draughts. This is not an issue when the shed is used for simple garden storage.

Shiplap Tongue and Groove Cladding

Shiplap tongue and groove cladding has a tight interlocking construction for significantly improved weather resistance compared to overlap cladding. The result is fewer draughts and less damp. The boards interlock via a tongue and a groove for a stronger construction. Shiplap refers to the scallop in the face of the board.

Shop shiplap tongue and groove sheds

Tongue and Groove Cladding

Standard tongue and groove shares the same tight interlocking construction as shiplap. In this case, the face of the board is flat for a sleeker, more modern finish.

Cladding thickness is measured in millimetres. Most standard shed cladding is 8-12mm thick.

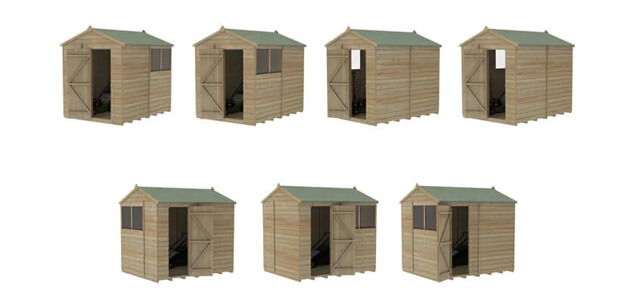

Forest’s Premium range of handcrafted tongue and groove sheds also includes a modular design. This makes for an easier assembly and stronger build, along with the chance to choose door and window placements.

Step Five: Floor and Roof Information

Solid wood floors and roofs, such as tongue & groove, offer superior insulation and strength to OSB options. As with the wall cladding, the thicker the better.

If buying a metal and plastic shed, always check whether it comes with flooring. Some models include floor support kits. These are frames which allow the customer to add their own wooden floor.

Roof Design

The style of the roof is a personal choice. The main three roof designs are apex, pent and reverse apex.

Apex Roof

A traditional apex roof has a high peak which runs from one gable end to the other. This offers increased headroom along the middle. The doors will be sited in one of the gable ends.

Pent Roof

A pent roof does not have a peak and slopes from front to back. This can make it easier to site under trees or alongside a fence. The sleek lines are popular in modern gardens. A lean-to roof refers specifically to a pent roof which slopes away from an adjacent wall or fence.

Reverse Apex

A reverse apex roof has the high peak of an apex roof. However, the doors are positioned on one of the longer sides, not a gable end. This may better suit some interior layouts, for example workshop sheds.

Roof Covering

A shed’s roof covering is usually made from felt. The most economic option is black sand felt which generally has a life span of 5 years. A stronger option is polyester-backed felt which benefits from extra fibre support and a longer life span of 15-25 years.

Certain high-end sheds may come with shingle roofs. They are long-lasting, very attractive and do not require a felt covering.

Glazing, either in terms of windows or a skylight, is essential when carrying out practical tasks inside a shed. For pure garden storage, it is not required. In fact, windowless sheds generally offer higher levels of security.

Opening windows provide ventilation, ideal for garden workshops and potting sheds.

The glazing in sheds will be real glass or an alternative such a styrene. The advantage of alternatives is that they are shatterproof. If the shed features real glass, toughened glass is a better alternative to horticultural glass.

Doors

Single doors allow for more wall space to be used for storage.

Double doors are particularly useful when storing larger items such as ride-on mowers.

Sliding doors are a sensible choice if the shed situated in a confined space.

Ideally, shed doors should be lockable to protect valuable tools and equipment. Mortice locks and rim locks, set in the body of the door, are best. A hasp and staple or similar non-key lock is a cheaper alternative. Turn buttons are purely designed to prevent the door(s) from swinging open, so offer weatherproof protection and privacy, but no real security.

Flexibility

For optimum flexibility of window and door placement, take a look at the 4Life Shed™ range, Timberdale Shed range, or Beckwood Shed range, all from Forest Garden, one of the UK’s leading shed manufacturers.

A shed must be built on a level, strong surface. An inferior base will result in the structure shifting, causing issues with doors, windows and cracks.

If using an existing base, ensure it is level and reliable before the shed is installed.

If installing a new base onto grass, the ground must be suitably prepared to make sure it is level with no more than a 65mm gradient across the width. All rocks, tree roots and other obstructions must be removed. A damp-proof membrane should be used.

More information about ground/base preparation before installation can be found here.

Concrete Bases

A concrete base can either be poured into a frame or consist of multiple concrete slabs. Both options benefit from the use of damp-poof membrane. If using slabs, ensure that there are no gaps between the slabs. Both a poured or a slab base should sit on a dressing of hardcore and sharp sand to allow for drainage. The resulting base should be level.

Wooden Bases

A wooden base is a frame of pressure treated joists which protect the shed from contact with the ground. If a wooden base is available to purchase with one of our sheds, it will appear in the shed’s accessory menu. If you want the shed AND the wooden base installed as part of our installation service, you must select this specific installation option.

Plastic Bases

Shedstore sell plastic shed bases as an easy to assemble kit. 100% recycled, these eco-friendly bases include membrane and, though light, are extremely strong and durable. They should be filled with pea gravel before use with larger sheds, as indicated by the instructions. Please note that plastic base installation is not offered with our installation services. It must be installed before the team arrive.

Once the shed is constructed, a power source can be added, if required. Solar power hubs offer easy DIY installation with power for lighting and other devices. Alternatively, a qualified electrician can run an armoured cable to the shed for mains electricity.

The 4Life Shed by Forest™

If you're looking to purchase a new shed and can afford a slightly higher initial spend, buying a pressure treated shed will save you a lot of time and money in the long term. 4Life Sheds are completely maintenance free - there is no need to ever apply treatment. Most other sheds require treatment once built - then yearly treatment thereafter. Forest 4Life Sheds have a number of features to ensure maximum durability and strength including solid boarded wooden floors, security door hinges, extra framing and so much more.

To learn more about the range click here.

Timberdale Shed's by Forest

With their tongue & groove build, substantial framing and high-end features, Forest’s Premium Timberdale Sheds offer you robust, practical and exceptionally stylish garden storage. Also, although there’s a slightly higher initial outlay when purchasing one of these sheds, the wood’s pressure-treated protection saves you both time and money in the long run, 25 Year Life Anti-Rot Guarantee means no time-consuming, costly retreatments are required.

To learn more about the range click here.

Beckwood Shed's by Forest

If you want to buy a Great British shed that offers more than just plain, old garden storage, choose a Forest Beckwood Shed. Supplied with a market-leading 25-year anti-rot guarantee as standard, Forest Beckwood Sheds are robust and durable, offering weather beating performance. The tightly-interlocking boards ensure the shed remains completely weathertight, while shiplap’s scalloped profile provides excellent rainwater runoff.

To learn more about the range click here.

Choose Your Delivery Day enables you to select the date when your product is delivered to you.

If a product is available for Choose Your Delivery Day, this will be shown on the icon and indicated next to the postcode checker.

When you enter your postcode into the checker, you will be offered a range of dates. You can then select one as part of the checkout process.

If Choose Your Delivery Day is not available, the lead time listed on the product page indicates when a shed will be available for dispatch. During that time period, the manufacturer will be in touch to arrange the delivery date.

Any changes made to an order can cause the delivery date to change, so check everything is correct before ordering.

Delivery is free with the vast majority of Shedstore’s sheds. However, some remote postcodes incur surcharges. Use the postcode checker on the product page to check if surcharges will apply to your delivery.

For those competent at DIY, each shed is supplied with an instruction manual. Be aware that constructing a shed is usually a two-person task due to the size and weight of the various components involved. An instruction manual will be provided and some manufacturers also provide links to videos that will support construction.

For those who would prefer a no-hassle, expert assembly, a professional installation service is available from most manufacturers. For more details, check the installation section under the full description on the product page for more details.

A suitable base, as described above, must be ready prior to the installation team’s visit.

Our friendly, UK-based customer service team are available to help answer any questions. Call them on 0333 003 0518 or use the Live Chat option onsite.

Take a look at our bestselling sheds below or view all our sheds here.